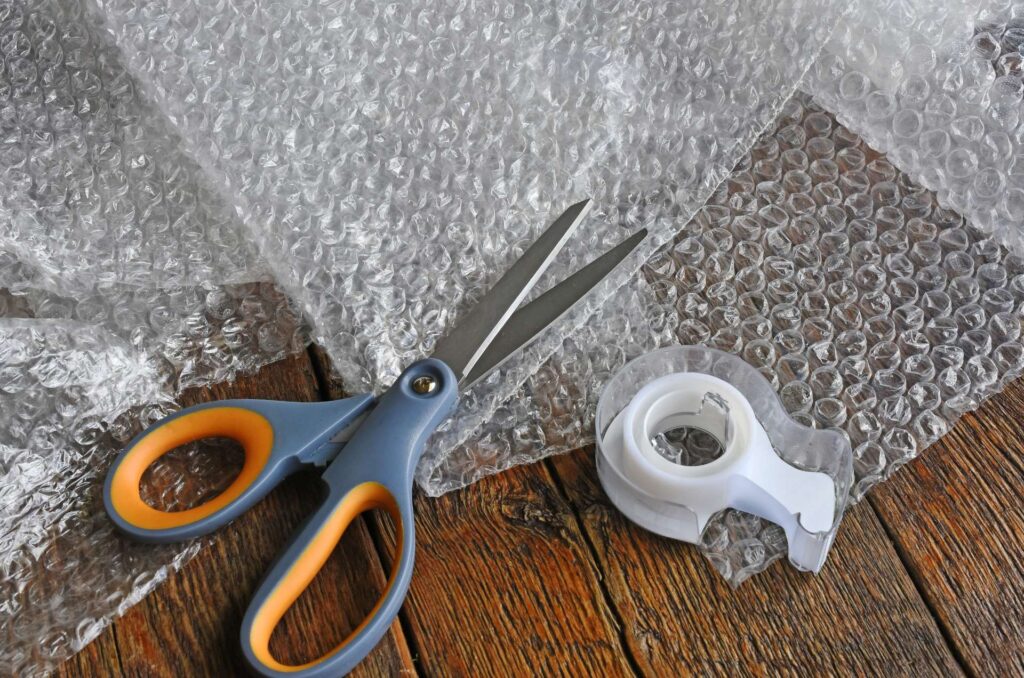

Cushioning & Voidfill Products

Cushioning & Voidfill Products are essential components in product packaging as they provide protection for the items being shipped. They help to absorb shock, prevent damage, and maintain the stability of products during transportation. These products come in various forms such as foam peanuts, bubble wraps, and paper fills, and can be easily customized to fit the specific size and shape of the product being packaged. The use of cushioning and void fill products is particularly important for fragile and delicate items such as electronics, glassware, and artwork, as it helps to reduce the risk of damage during transit.

Cushioning & Voidfill Options

- Bubble Cushioning Material

- Foam Wraps

- Special Foams & Die Cuts

- Foam in Place System

- Cellulose Wadding

- Packing & Stuffing Paper*

- Single Face Corrugated

- Bubble Wrap

- Single Face Corrugated

- Inflatable Dunnage Bags

- Polyethylene Loose Fill

- Loose Fill Hoppers

- Bulk Dispensing System

- Foam & Bubble Cutters

Void Fill Packaging FAQs

Void fill packaging refers to materials used to fill empty spaces within a shipping box or container, preventing the contents from shifting during transit. This helps protect items from damage by absorbing shocks and vibrations.

The best void fill packaging depends on the specific needs of the product being shipped. Options include bubble cushioning material, foam wraps, special foams and die cuts, foam-in-place systems, cellulose wadding, packing and stuffing paper, single-face corrugated, inflatable dunnage bags, polyethylene loose fill, and loose fill hoppers. Each material offers unique benefits, so selecting the appropriate one is crucial for optimal protection.

Cost-effective void fill options include paper and air cushions, as they provide good protection at a relatively low cost. Paper can be crumpled or shredded to fill space effectively, while air cushions offer lightweight protection, reducing overall shipping costs.

Dunnage packaging consists of materials used to secure and protect goods during transportation. It acts as a buffer, safeguarding products from damage by absorbing shock, bracing items within containers, and preventing movement that could lead to wear or breakage.

Yes, void fill packaging can be eco-friendly. Materials such as paper void fill, cellulose wadding, and biodegradable loose fill are sustainable options that provide protection while minimizing environmental impact.

The purpose of an air cushion is to provide lightweight, flexible protection for items during shipping. Air cushions fill voids within packaging, preventing movement and absorbing shocks to safeguard products from damage.

Air cushions provide lightweight, flexible protection and are best for less fragile items. Foam offers more dense and reliable cushioning, making it suitable for heavier or more delicate items that need extra support.

Products that are lightweight, non-fragile, and have smooth surfaces are best suited for air cushion void fill. This type of packaging works well for electronics, boxed items, and various consumer goods that require minimal movement protection.

Disadvantages of air cushions include their reliance on plastic materials, which may not be environmentally friendly, and the need for specialized equipment to inflate them. Additionally, they may not provide adequate protection for very heavy or sharp-edged items.

Yes, some void fill materials, such as printed paper, can be customized with a brand’s logo or messaging to enhance unboxing experiences and reinforce brand identity.

Ready to upgrade your packaging strategy? Let's do it together!

Fill out the form below and we will be in contact.